Head Office

- Daniit A/S

- Jyllandsgade 42

- DK- 6400 Sønderborg

- : +45 73 42 36 36

- Mail@daniit.com

- CVR nr. DK-37237310

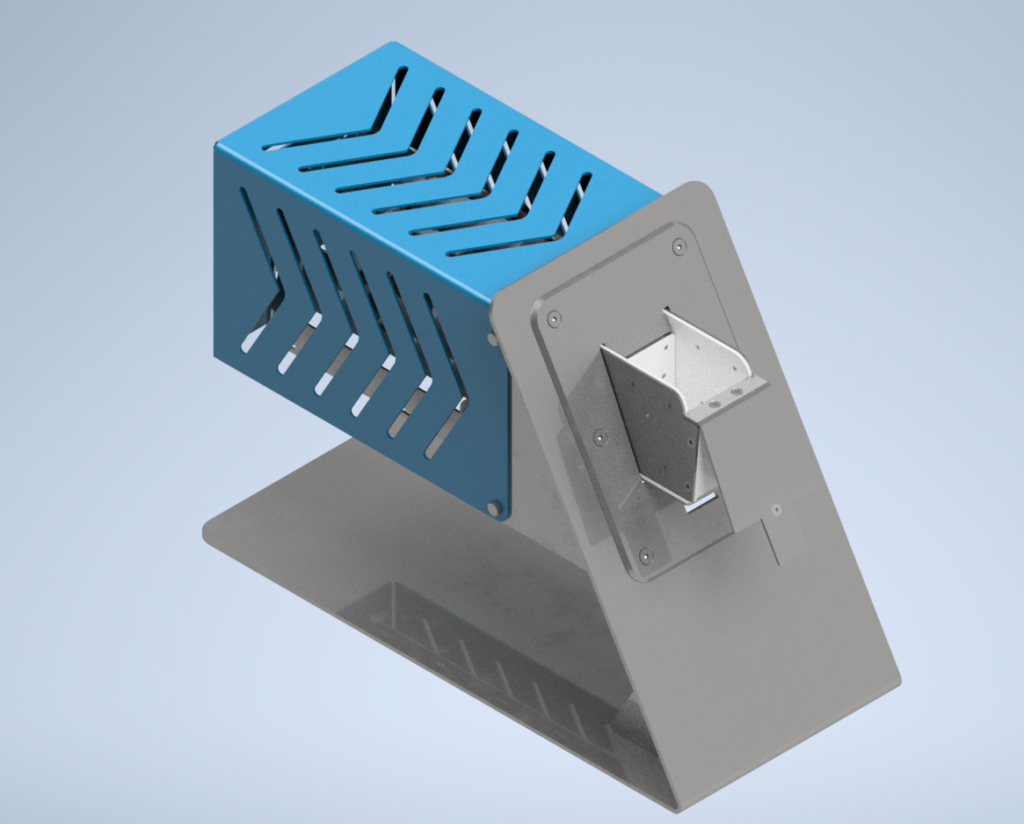

The purpose of a PTM M23 is to automatically measure the core temperatures of the finished product that comes out of a pellet presser.

The TAD measures a quantity of finished pellets that have been compressed to a mass.

When measurement is completed, the measured mass is either collected outside the presser or returned to the production flow in the presser.

If the temperature measured falls outside specified reference temperatures, an alarm sounds and a single action can be automatically carried out.

Measured temperatures are collated, and can be automatically included in the factory’s overall quality assurance and energy optimisation system.

Do you want to secure a stable and safe operation?

Our technicians will assist you with optimised maintenance, and secure easy access to spare parts.

In the event of breakdown, we can come out to you at short notice. Contact us today for a solution that mirrors your needs.