Daniit FCS - Feed Controle System

Feed security is guaranteed by sophisticated batch handling throughout the production process, from intake of raw materials to bulk loading and discharge.

Daniit’s FCS process control and traceability system includes advanced functionality for accurate and rapid dosage and weighing with a high degree of repetition. Comprehensive and detailed documentation is supplied through long-term data logging, which is stored in reliable industrial databases.

COMPLETE FEED CONTROL

Daniit´s FCS is the obvious choice for a cost-effective operation

- Multiple-level recipes/handling of embedded pre-mix recipes

- Precise dosage and repetition

- Full traceability of identification numbers

- Flexible monitoring of silo exchange via RFID (radio)

- Approval of hand additives using barcodes

- Automatic change of dosing silo when status is ‘empty’

- Comprehensive batch reporting

- Long-term logging of production data

- Calculation of power consumption per kilo

- Self-operated bulk discharge

- Multiple (up to 16) user interface monitors

- Remote login to online service and operation

- User setup of email and SMS messages

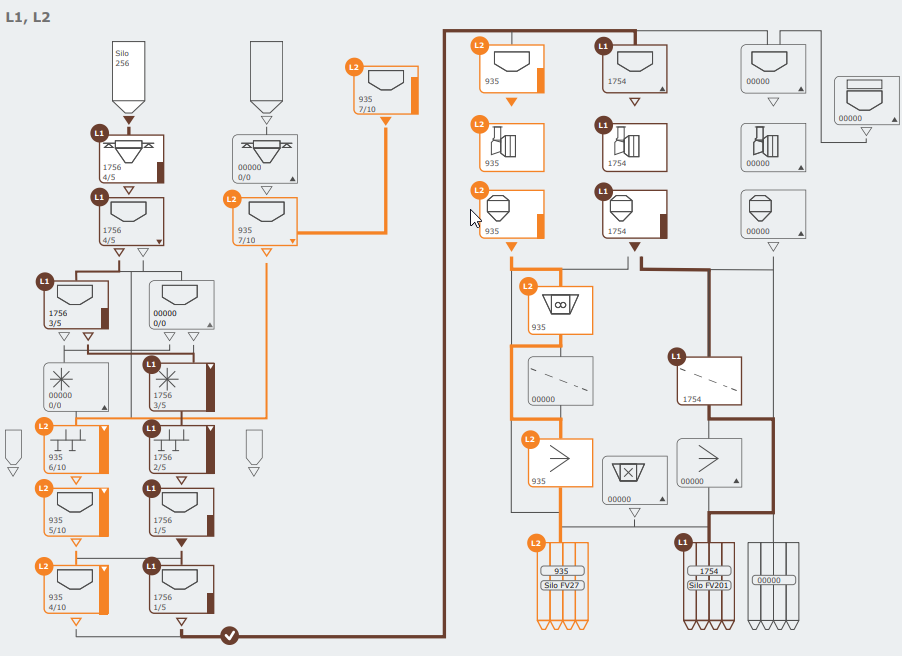

SCADA

Daniit’s SCADA is built on the latest ISA 101 standard, where a ‘level’ split user interface always ensures an optimal overview and fast intuitive navigation. The SCADA solution’s design is based on feedback from interviews with users, and collaboration with experts in the area. Daniit’s standard SCADA solution gives you plenty of help along the way to controlling your production. If you require unique functions for your specific needs to be met, Daniit’s SCADA solution is flexible and can easily be implemented.

- User administration

- “Ealy warning”

- Reporting

- Alarms, notification and events

- Intuitive

- Recept management

- Bach

- Recept management

- and more

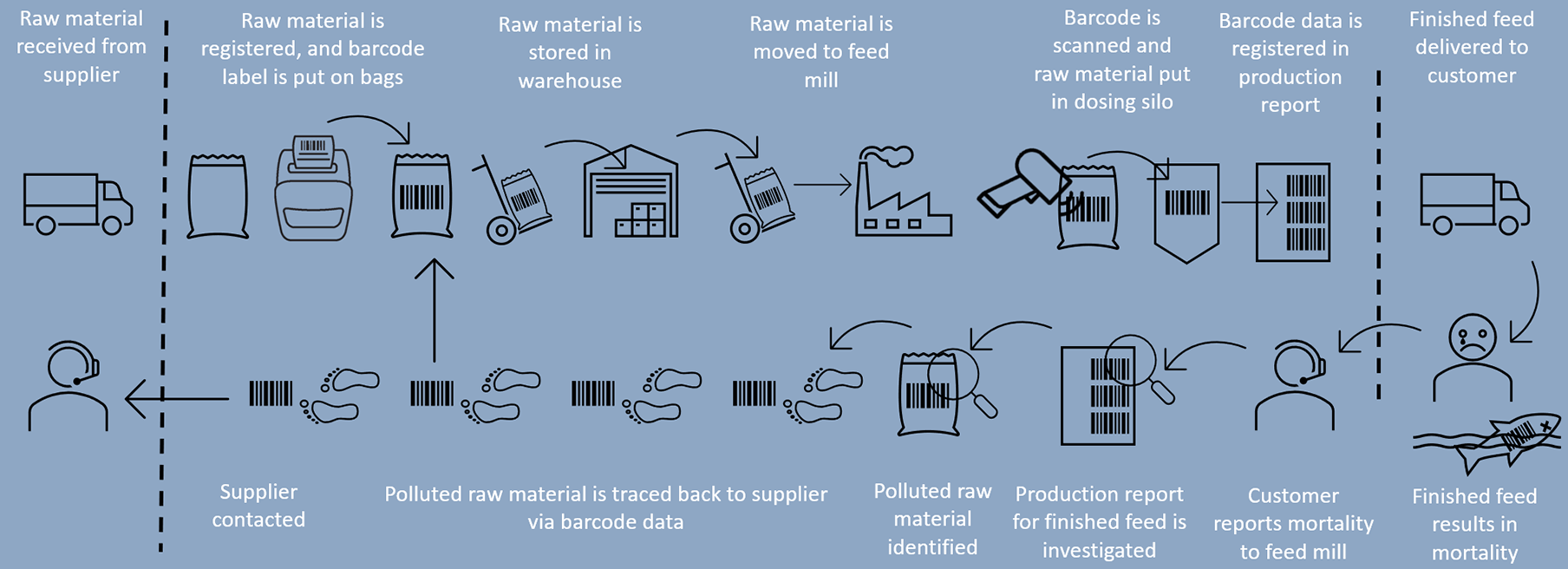

TRACEABILITY

Each batch (lot) of a given raw material received in your company is assigned a unique code, a kind of CPR number.

In connection with the manufacture of a product (finished product), “digital footprints” are set aside for every transaction the raw material in question makes during production, e.g. when dosing via a weight.

This “digital footprint” refers to the raw material’s unique code. These “digital footprints” are stored together with the product (finished product).

In the event of a recall of a product, your company can, via the digital footprints, quickly form an overview of which raw materials the product consists of, and can identify the problematic raw material(s).

At the same time, it can be identified in which other products the problematic raw material(s) are also included.

Our services

Do you want to secure a stable and safe operation?

Our technicians will assist you with optimised maintenance, and secure easy access to spare parts.

In the event of breakdown, we can come out to you at short notice. Contact us today for a solution that mirrors your needs.